What you'll see in this post are pictorial/visual examples on Development (and refinements) in a design journal. The examples do not represent any complete section of a journal. They serve as a starting point - an example - a demonstration - a suggestion - a recommendation - etc. to show what sort of contents may go into, say development, and how you can present your research and information in the journal.

Use them as a reference and a guide to start or to improve your journal. Make informed choices on your own on what your takeaways should be after looking at the materials in here. Do not copy.

If you find this helpful, I would love to hear from you. If you have suggestions, please do not hesitate to link up with me.

Topics you'll find below:

1) Ideas Generation (SAMPLES) using Existing Products as Starter/Inspirations [Updated 39 June 2017]

2) Selecting (SAMPLES) Best Idea for Development (using Decision Matrix) [Updated 39 June 2017]

3) DEVELOPMENT [SHAPE AND FORM] [Updated 39 June 2017]

4) DEVELOPMENT (SHAPE & FORM and FUNCTIONALITY) [Updated 27 July 2017]

5) DEVELOPMENT (Determine SIZES with CRITICAL DIMENSIONS) [Updated 28 July 2017]

6) DEVELOPMENT (Determine SIZES with ANTROPOMETRIC DATA) [updated 28 July 2017]

Ideas Generation (SAMPLES) using Existing Products as Starter/Inspirations

(email me for more details to learn about using Existing Products as Starter/Inspirations for Ideas Generation)

First two images shows ideas generation using existing products as initial source of inspirations. Existing products used have nothing to do with stationary holders.

Image above shows ideas combined to create a new hybrid. This is one of the outcomes you want to have when generating ideas. Combining ideas can give you unexpected interesting solutions.

Selecting (SAMPLES) Best Idea for Development

(using Decision Matrix)

(email me for more details to learn about using the above)

The Decision Matrix is one of the most convenient way to select a best idea from a few good ones. Here I selected five ideas for consideration where one of them will be selected for development. I set a few criterion what makes up the attributes for considering the best idea. Then use weightage and ratings for each idea for computation.

The above example shows Idea 4 scoring the highest.

Idea 4 will be redrawn for development. See below.

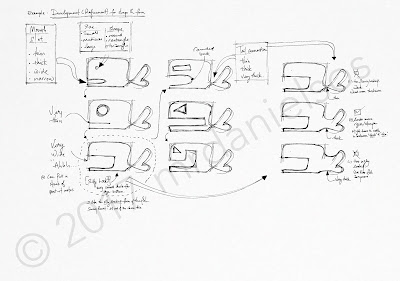

Development (SAMPLES) using Attribute Listing / Morphological Method

DEVELOPMENT [SHAPE AND FORM]

(email me for more details to learn about using the above)

Attribute Listing or Morphological Analysis (and also SCAMPER) are not just Ideation tools. They can also be used for refinement purposes.

Individual parts / features are selected one at a time to make changes one change at a time. E.g. I pick the body to make changes to shapes and forms. Then I refer to the Morphological table and looked under, say 'Shape', that could be circle, square or a triangle, etc. I proceed to change the body cross-section to the various shapes - just to see how my original selected idea might look like with different cross-sectional shapes. At this moment I would also need to consider the overall functionality as while you change anything, in this case the cross-sectional shape, the change will affect the way it works (or how it will be holding/storing the pens or pencils) or how the 'legs' should be installed, etc.

When developing a product's shape and form you MUST always keep in mind the idea of working towards finalising (e.g. the shape, size, dimensions, colors, jointing methods, etc) a solution in mind. This is NOT like in the exploratory mode when you were generating ideas earlier on.

Above is an example of my student's chosen idea for development. I made use of the attributes for each part of the object (in this case the difference parts of the fish) and made a couple more refinements on its shape and form. NOTE: What is not shown in the above example are placement pens and pencils within each possible variety of shapes. You should put them in.

DEVELOPMENT (SHAPE & FORM and FUNCTIONALITY)

|

| Shown on the right is a sample of how I draw a decision in Isometric 3-dimensions. |

Developing a solution's shape and form without considering its functionality is quite useless. A simple way to consider functionalities is to draw your pens or pencils and/or rulers into your proposed holders (or whatever you may be designing for) in every iterations that you make along the way. Doing so enables you to think about how effective the new solution are holding or storing the items. And in turn may inspire you to make further changes or improvements to the shape and form to achieve better functionalities. - see image below. [Updated 26 July 2017]

Note that other aspects like ergonomics, sizes, materials, jointing methods, etc. that will come into play whenever any shapes and form is changed is not specifically discussed here. However you should start to consider them simultaneously if these considerations appear as you develop the product. For example, the moment I change the inverted triangular cross-section body into a rounded rectangular cross-sectional body, it may require a change of materials or jointing methods. Further development by making it a laminated piece also require decisions of materials. If there will be a change of materials there might be a change of the way of jointing. etc. [Updated 27 July 2017]

The image above is an extension of further refinement focusing on the main body of the holder. And showing how any changes in shape can affect functionality (and also the choice of materials and manufacturing methods).

DEVELOPMENT

(Determine SIZES with CRITICAL DIMENSIONS)

|

| Use of Critical Dimensions |

There will come to a point in the development phase where it's time to work out the dimensions of each parts and eventually the overall dimensions of the product. There are three possible ways you can obtain those data:

1) Use of Critical Dimensions (i.e. the objects that the product is holding/storing/interacting with) to determine the sizes of space needed, leading to the sizes of the parts making up the solution.

2) Use of Anthropometric Data (i.e. the measurement of relevant body parts and its relative end positions) to determine the critical height (e.g. for the height of a seat, or for the tallest shelve, etc.) of certain parts/features or the overall (max. or min.) dimensions of a solution.

3) Use of the area / volume of the Environmental Space of which the product will be used or placed. Usually you'll have a maximum or minimum allowable space for the new solution. This can be a good starter to set a minimum or maximum size for your new solution.

In the example above, I know I need to place some pencils. So I use the diameters of my pencils laid side by side to determine the width of the storage space. I want to stack the pencil up to maximum 2 layer. So I use twice the diameter of a typical pencil to determine what the minimum height of the 'side panels' should be. Which I eventually round it off to 20mm.

To get Critical Dimension data, you simply measure off (and take average of similar ones) relevant features of the items that is going to be held or stored. In this case the average diameter and length of a pencil seemed very critical for me to determine the area of the 'body' and the height of the 'side panels' (to prevent the pencils from falling off sideways.

I found a tabulated table from the internet and used that as my reference. (Note that I acknowledged the source.) [Updated 28 July 2017]

DEVELOPMENT

(Determine SIZES with ANTROPOMETRIC DATA)

|

| Use of Anthropometric Data |

The example shown above is not complete. I want to make use of Anthropometric Data to decide on the best overall size for my new solution. So that if I need to move it around, it will be comfortable to be picked up with my bare hands. The size and weight must feel right. Which part of my body should I measure? Can you work it out on your own?

Compare the result with data and size decision made using Critical Dimension data. Combine both data together to get a conclusive optimum overall size. [Updated 28 July 2017]

Conclusion:

A decision will have to be made for every stage of refinement, be it shape and forms, proportions, size and dimensions, jointing and construction methods, colors, or finishing, etc. Eventually at the end of the development phase, you will have all the information and data ready for producing your working drawings and production schedule.